|

|

Dani Stahl, Switzerland |

|

|

Tom Leemans, Illinois

Ever since meeting Dean at GLLI in 1999, where I fell in love with the sexy good looks of his BBO bows, I'd been itching to try building one myself. “Purple Haze” was my first BBO bow and although I had to learn some lessons on tillering a reflex/deflex bow as I went, I couldn't have been more pleased with the way it turned out. I shot where I looked every time and it was as smooth as can be.

Always being one to have my bows a little different than others, I opted for the wild dye job and the purple suede handle leather. My ever-present shop assistant Emily helped lace up the handle and added the bead treatment herself. That bow has since found its way into the hands of a friend. I hope he enjoys it as much as I did. We've made more bows since then and plan on many more, including a recurve or two. Thanks to Dean for his instruction and advice. Most of us wouldn't be building bows without his help.

|

|

Bruce Martin, South Carolina

It get's under your skin working on these bamboo-backed bows. The first one I made was from an r/d blank from Dean and actually turned out good from the standpoint of tiller, in the end. But the big mistake I made on that bow, a reflex-deflex design, was dishing the dips to create a hinge. Correcting that mistake, by using the walkie-talkie stick, left me with a nice bow that draws 43# at 28 inches... about 10# less than my target weight, and I had to shorten it to 62 inches to achieve that! That bow is now proudly owned by a 14 year old friend.

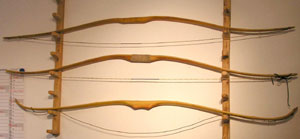

I've made several bows since then, steadily improving. The most rapid progress I made was with straight-limbed bows with about 3 inches of backset in the jig. They are easier to tiller with the walkie-talkie stick. I made 3 of these bows from osage and bamboo and made target weight on each as I tillered. I experimented with 64, 66 and 68 inch bows. One of these, a 64 inch bow, is on Dean's website, and pulls 70# at 28 inches.

After gaining experience and confidence from the straight-limbed bows, I've gone back to the reflex-deflex design. Such bows shoot faster with less hand shock than the straight-limbed bows. The bows I've made are 60 to 65# @ 28 inches and shoot a 700+ grain birch arrow real well.

I'm still learning and still having fun making them.

|

|

|

Richard Oppelt, Germany |

|

Stan Mercer, Oregon

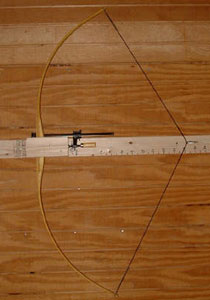

This is my second attempt at building a BBO. My first bow broke from heating it too much too fast, causing a separation in the glue joint, subsequently causing a limb to let go. For my second bow I chose to buy a glued up blank from Dean, straight-limb style. Once again I heated the bow too much too fast in my dry box, but this time was able to fix the error with CA glue, thanks to a conversation with Dean. That being squared away I finished faceting the limbs with a rasp, cleaned them up and shaped them with a Bowyer’s Edge, and put it on the tiller tree. Already the bow was pleasing. A little fine tuning near the handle, and some work to get the outer limbs bending more, and I was ready to finesse in tiller and weight. Seemed fairly easy with the use of walkie-talkie.

As Dean says in his video, the real work in making these bows is in the glue-up. Buying a blank was the right choice for me at this point in my bowmaking endeavors. Finishing the blank was really a matter of studying the accompanying pamphlet, watching the video and taking my time. I e-mailed Dean a couple of times along the way as well, just to make sure. As a result, I ended up with a bow that was well tillered, 67# @ 28 inches, that is now 63# after shooting in and finish sanding. May try a reflex-deflex in the future, but in the meantime I plan on enjoying a first class hunting bow.

The third photo shows a three shot group at about 20 paces, taken before I'd even put in a handle wrap. The bow holds much promise for this fall.

|

|

|

Gail Darling, Kansas

I contacted Dean and purchased his video and book on making bows. I was hooked, and since have made four Bows. My first bow was for my grandson who is 9 years old. It came out at 60” 30#@28” draw. A real sweet shooter, just perfect for a youngster to shoot. The second Bow broke at 45# @ only 24” draw. I thinned the bamboo too much over the nodes. The third bow raised splinters on the back of the bamboo because again I filed too much off the nodes, weakening the bow. It can be repaired according to the instructions on Dean's website (Handicapping the Odds). The fourth Bow came out just as I had planned. It is 60 1/2” long, 65#@24” draw. It is a real sweet shooter, very fast and a hard hitter. This is the bow that I will deer hunt with in Missouri and Kansas this season.

|

|

|

Dale Gregory |

|

|

Joe Territa, Louisiana

After searching the web, I found what I needed to build my own fiberglass and wood-laminated recurve. Shortly thereafter I came across a picture of a bamboo-backed bow. I thought it was the finest looking thing I had ever seen, and suddenly my recurve wasn't quite so beautiful any more. Through Primitive Archer Magazine, I found the source I needed for information to build my own.

That was three years ago and some thirty or so bamboo-backed osage bows. I have successfully built and either given away or sold practically all of my bows since then. I became obsessed with making these beautiful bows, and still think today they are the finest looking bows a man could own.

I met Dean Torges at the 2002 MoJam for the first time, but we'd already spoken many times and I felt like I already knew him. He'd helped me through all sorts of problems—at least I thought they were problems. I owe all of my bowmaking skills to him, and he owes his crawfish eating skills and his source for mudbugs to me.

Whether you prefer target shooting year round or just a good hunting bow, his design of the reflex/deflex longbow is superior to any other primitive bow I've ever shot. I live in South Louisiana and have a small swamp behind my home. I name all of my bows "The Swampfire Bow." They are all beautiful and very durable, and getting pretty darn popular around here. |

|

Rusty "Trashwood" Craine, Texas

Dean's BBO in the R/D is a fine hunting bow, one of the sweetest shooting wooden hunting bows I have ever shot. Over the past few years of building wooden bows I have come to favor a more primitive style bow on the shorter side, one that must bend through the handle. The bendy-handle bows are not nearly as sweet. They have a Jeep feel as compared to a Land Rover.

I wanted to try the same building process that Dean advances in his video to build a short Indian style bow. This bow is made exactly by the process given in Dean's video, including the facets and trapped back.

59" NTN, 1 7/16" wide thru mid limb, 72# at 26". After 2 years of hunting and practice shooting the bow maintains 2 3/8" of reflex. It's not necessarily on the sweet shooting side and about as forgiving as a brick in a power dive, but it's a fire ball and powerful enough to take after anything in North America I thought I was big enough to drag home.

Dean's building process can be used to build a bow of your own design. Perhaps it might not be any sweeter shooting than Dean's R/D design, but if you've a mind to follow a different path, his techniques and process might help you build a bow that's just the ticket for you. |

|

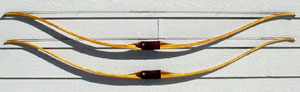

Mike Westvang, Texas

I have been building BBOs using Dean's process as shown on the video since it was published. Here is an example of the bows. This one was laid up in the "high dollar" configuration to better handle the light arrows used in target shooting. It is 46# and is 62" ntn. I enjoy building and shooting these bows very much and have been able to take an elk the past three years with BBO's of Dean's design. They shoot fast and true. |

|

Dan Ryan, Alaska

These bamboo backed bows are addictive! I've been hooked for almost a decade now, experimenting with different woods, heat treating the bamboo etc. etc. Problem with my early bamboo-backed bows was that I approached the whole building process with a laminated glass bow mindset. No need to elaborate. I'm going in the right direction now though.

I've used the Torges process to build elm, mulberry and vertical pressed bamboo bows and am going to try goncalo alves in the near future. Has anyone out there tried goncalo? If so I'd like to hear from you. I don't think you can beat osage but a change of pace is good sometimes.

I thought Dean was borderline showing off a bit removing those long ultra thin curls with his bowyers edge tool in the video. :-) Now that I own one myself, I do the same thing. Have you ever noticed the look on a good fiddle player's face when he is doing a turn around on Faded Love with a perfectly tuned insturment? I'm sure that is the look I had the first time I used my edge tool sharpened and adjusted per the instructions with the tool. My bow building hobby is much easier now. If you don't have a Bowyer's Edge, do yourself a favor and get one. You won't be sorry.

The osage in my photos came from half of the well-seasoned fence post shown with the bows. Notice the olive green coloring in the lower end of the post. I'd say it was in the ground a very long time. |

|

|

Frank Reinshagen, Germany

Bamboo backed Plumwood with Ebony insert in grip. The Plumwood pieces i found in the basement of my parents house. It's about 30 years old and it's very dark reddish brow colour and shows purple flames. The billets I got from that were too short, so the handle is spliced in. Total length 67.5" / ntn 66"; width tapers from 1 5/8" at fade out to 7/16" at tip; 60#@29"; bit less then 1" of reflex right after unbracing. |

|