The Principle of Complements

©Dean Torges/The Bowyer's Edge™

A common misconception is that a flatbow must have a flat belly. Historically, flatbows do sometimes appear with flat bellies, but they can just as well sport radiused or rounded bellies. Compared to a longbow, a flatbow is a bow that has been made wider so it can be made shorter, regardless of its belly shape.

A common misconception is that a flatbow must have a flat belly. Historically, flatbows do sometimes appear with flat bellies, but they can just as well sport radiused or rounded bellies. Compared to a longbow, a flatbow is a bow that has been made wider so it can be made shorter, regardless of its belly shape.

The term flatbow is simply a designation for one of three basic bow styles--flatbow, longbow and recurve (which, depending upon materials used, can be constructed as self, laminated and composite bows). Some English longbows used in target archery in the 30's and 40's were rendered with flat bellies, yet they are hardly regarded as flatbows. In short, the shape of a bow's belly does not determine either its style or its kind. I mention this elementary truth to disabuse some of us of the mind-lock that a flatbow must have a flat belly.

Tim Baker has done some excellent research in vol. I of the Traditional Bowyer's Bibles, resurrecting the work of such pioneers of bow limb design as Hickman, Klopsteg and Nagler. As a consequence, many modern bowyers employ flat bellies in the belief that under all circumstances flat bellies place less stress on bow limbs than radiused bellies and are therefore necessarily desirable. Let's look a little past theory and a little closer at practice.

I have several objections to a flat belly on a wooden bow made from a tree stave, especially on a flatbow used for a hunting weapon, and they are catalogued in "Hunting the Osage Bow." I would like here to expand on just one of them--the practical tool problems encountered in executing a flat belly on a typical tree stave.

As a general woodworking principle, a flat hand tool mates effectively to a radiused surface, and a convex tool mates well to a flat surface. This "principle of complements" seems contradictory until you put it into practice. In hand tool practice, two dimensional areas like rough sawn wide boards are made flat by hand planes called scrub planes. Scrub planes employ slightly radiused plane irons. The boards are finished up with hand scrapers that bow in the middle to scoop along part of their length, forming a radius. In this way, rounded cutting surfaces create flat work surfaces. On the other hand, such three dimensional items as cabriole legs, with their curves and flowing lines, are shaped with flat tools like spokeshaves and rasps. Thus, flat tools create rounded work surfaces.

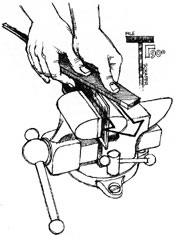

It is difficult to create a flat surface with a flat tool unless it completely overrides the work surface in the same way that a jointer plane overlaps the edge of a board. If you doubt this, try using a rasp, a scraper or a spokeshave (the tools most commonly used on flat bellies) to flatten the edges of two boards for the purpose of gluing them together. This "principle of complements" carries over wholesale to shaping limbs and bow handles, which are three dimensional. It has serious implications in tillering wooden bows precisely.

A good bow amounts to nothing more than dry wood expertly tillered. If we agree on that, then once the wood is dry, a bowyer should choose as his means of craftsmanship the work methods that help him arrive at expert tiller. Once we graduate from flat board bows, the problem with executing flat bellies to arrive at expert tiller becomes apparent. Board bows are effectively two dimensional and really present few tool problems. However, tree staves, especially those commonly found in osage, have undulating and irregular backs. They force us to consider bows in three dimensions. This complication, or added dimension, may be less apparent in most white wood staves, which generally are much less gnarly and irregular than osage, but it nevertheless exists in every tree stave to some extent.

Imposing a flat belly with flat hand tools (rasps, scrapers, spokeshaves, etc) becomes an arduous and imprecise task. When the limbs gain width to lose length, the problems and difficulties increase all the more because precise tiller becomes more critical to success. In addition, if you have to deal with the nuances and irregularities of a tree stave, you've increased the likelihood another measure that you will forget about tiller, and get lost upon the flat theory of the bow universe.

The reason is that you are attempting to distribute flex precisely along the length of the limb, but the nature of hand tools does not allow you to bust them to purposes for which they were not intended. You must struggle against the current to achieve the effect you wish, and it is easy to tire, lose sight of your real goal (an expertly tillered bow) and settle instead for a flat belly. You thereby create a two-dimensional effect upon a stave that requires three-dimensional considerations. The wider, the shorter and the more irregular the stave, the bigger this possibility becomes.

If you want to do wide flat bellies on tree staves, it is best to swim with the current--of the 110 or 220 volt variety. These bellies are worked effectively with grinders and drum sanders because grinders and drum sanders bring a radiused tool to a flat surface. The "principle of complement" in electrical action. With milled and flattened boards in the cabinet shop, for comparison, the same principle finds expression through cylindrical jointer and planer cutterheads.

Archery equipment manufacturers in the 40's and 50's mass produced numerous bows cheaply and quickly with power equipment. Most of them were board-stave flat-bellied lemonwood or hickory recurved self bows. Some of the more prominent longbow bowyers of that era, including Keasey, Ullrich and Styles, influenced for the most part by the flatbow results obtained by Hickman in target archery competitions, tillered some English longbows with flat bellies, too. Some of these bows were tillered with power equipment.

Good results could be obtained because the flat belly surface on their target bows were usually less than an inch across over most of the working limb. Moreover, the fluctuations on the sapwood back of yew bows could be bulldozed over somewhat and, if deemed necessary, landfilled with rawhide. Under these conditions (narrow belly left to right), the average do-it-yourself bowyer could with some facility use hand tools and still finesse tiller. Narrow limb widths permitted these bow to take on a two dimensional appearance. However, there was not much future in such bows because at the low draw weights and light arrow weights preferred for target archery, they were outperformed by flatbows.

Precise, controlled work on bows tillered from tree staves requires a thoughtful approach through hand tools and a regard for all three dimensions. The tool that I use after the drawknife when revealing a stave's back is a Stanley or Record spokeshave. I grind its blade into a slightly convex shape so I can quickly get right down onto the grainy spring growth of osage and follow it wherever it leads. You couldn't do that with a straight-edged blade without the greatly increased hazard of scalping the areas surrounding your concentration.

The last tool I use on the back of a tree stave is a gooseneck scraper. Its convex edge allows me to follow a growth ring precisely and perfectly, following humps, dips and pin knot clusters exactly as I need to. With it I could make a dead flat back if I wanted to or needed to. I could not with a straight edged cabinet scraper any more than I could with an orthodox spokeshave. And for the same reasons.

You can bring these same tools over to a stave bow and work them in a similar manner if you insist on executing a flat belly, but the task is made more arduous and risky because you are stepping down through growth rings, because you sometimes need to leave islands of growth in weak areas, and because a spokeshave, even with a modified convex blade, does not handle these areas with finesse.

You can move quickly, confidently and precisely over a tree stave through the employment of a succession of hand tools perfectly suited to the task of fashioning a radiused belly. The requirements are fundamental to entering any facet of real archery--you first must invest some time to gain a little skill, understanding and experience. In the final analysis, expertly tillering bows consists of allowing hand tools to do what they are designed to do rather than imposing your will upon them and drafting them to a theoretical mission.

Eventually, reality trumps theory. You can hasten this outcome by being friends with your tools. Allow them to work for you. Your bows will like you better for it. You may like them better, too.

"Carve a little wood, pull a few strings, and sometimes magic happens." --Gepetto